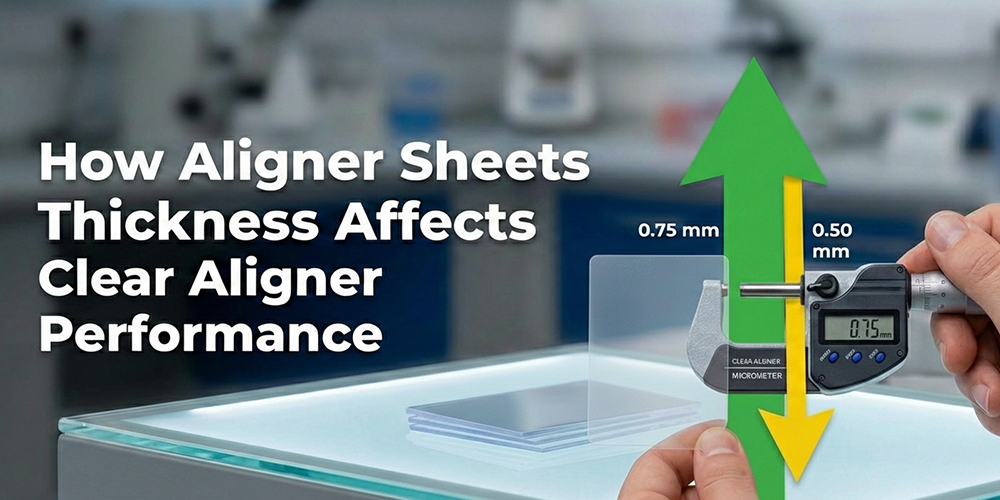

How Aligner Sheets Thickness Affects Clear Aligner Performance

Aligner sheets thickness sounds like a small detail.

It isn’t.

It’s one of those things nobody worries about at first.

Until aligners crack.

Or feel uncomfortable.

Or just stop moving teeth the way they should.

If you’ve ever asked yourself:

“Why does this aligner feel too stiff?”

“Why does retention drop halfway through treatment?”

“Am I using the right thickness, or just what everyone else uses?”

You’re not overthinking it.

You’re asking the right question.

And it all comes back to aligner sheets thickness.

Why thickness matters more than material alone

Most people obsess over material.

PETG vs TPU.

Single-layer vs multi-layer.

Material matters.

But thickness decides how that material behaves in real life.

Same PETG.

Different thickness.

Completely different clinical outcome.

Thickness controls three things that actually move the needle:

Force delivery

Patient comfort

Durability across wear time

Get thickness wrong.

And even the best material underperforms.

What “aligner sheets thickness” really changes in practice

Let’s keep this practical.

Thickness directly affects:

Initial force applied to the tooth

Force decay over time

Flexibility during insertion and removal

Crack resistance after thermoforming

That’s not theory.

That’s daily lab reality.

Thin aligner sheets (0.5–0.6mm): where they shine, where they fail

Thin sheets are popular for a reason.

They’re:

Easier to thermoform

More comfortable for patients

Less noticeable in the mouth

But here’s the trade-off nobody likes talking about.

Thin aligners:

Deliver lighter forces

Lose force faster

Deform more easily after a few days

They work well for:

Minor movements

Refinement stages

Short wear cycles

They struggle with:

Complex movements

Long wear intervals

Patients who are rough on aligners

Thin doesn’t mean bad.

It just means limited.

Medium thickness (0.75mm): the industry workhorse

If there’s a “safe zone” in aligner sheets thickness, this is it.

0.75mm sits right in the middle.

Enough rigidity to move teeth.

Enough flexibility to stay comfortable.

Clinically, this thickness:

Balances force and comfort

Holds shape better over time

Works across most treatment stages

That’s why many labs default to it.

Not because it’s perfect.

Because it’s predictable.

For PETG thermoforming sheets, this thickness is often the sweet spot.

Thick aligner sheets (1.0mm+): power with a price

Thicker aligners look impressive on paper.

More material.

More strength.

More force.

But more isn’t always better.

Thicker sheets:

Deliver higher initial force

Feel stiffer during insertion

Can reduce patient compliance

They’re useful when:

Significant tooth movement is required

Retention is the top priority

Aligners need to last longer per stage

They become a problem when:

Comfort drops

Patients struggle to seat aligners

Excess force causes unwanted side effects

Thickness should match the job.

Not ego.

Thermoforming changes thickness more than you think

Here’s something labs learn the hard way.

The thickness you buy

is not the thickness you end up with.

During thermoforming:

Material stretches

Thickness reduces unevenly

Occlusal and gingival areas behave differently

That means a “0.75mm sheet”

might end up thinner in critical zones.

This is why consistent PETG quality matters.

And why sheet uniformity isn’t a small detail.

Low-quality sheets exaggerate thinning.

High-quality PETG holds structure better.

One thickness for all stages? That’s lazy thinking

Real talk.

Using the same aligner sheets thickness for every stage is convenient.

It’s also limiting outcomes.

Smarter approach:

Thinner sheets for initial alignment

Medium thickness for controlled movement

Thicker sheets for retention

You don’t need more complexity.

You need intentional choices.

How I’d choose thickness if I were running a lab today

Here’s my no-BS framework.

I’d ask three questions:

What movement is required?

How long is each wear cycle?

How compliant is the patient group?

Then I’d match thickness to reality.

Not trends.

Not supplier hype.

And I’d test.

Always test.

Common mistakes I see with aligner sheets thickness

I see the same errors again and again.

Choosing thickness based on price alone

Copying competitors without understanding why

Ignoring thermoforming shrinkage

Assuming thicker = better results

None of these are strategy.

They’re shortcuts.

FAQs

What is the best aligner sheets thickness for PETG?

There is no single “best” thickness.

0.75mm is commonly used because it balances force and comfort.

Final choice depends on treatment stage and movement complexity.

Does thicker aligner mean faster tooth movement?

Not necessarily.

Too much force can reduce efficiency and comfort.

Controlled force beats brute force every time.

Does thermoforming reduce aligner thickness?

Yes.

All thermoforming processes reduce thickness to some degree.

Higher-quality PETG reduces uneven thinning.

Should labs stock multiple thickness options?

Absolutely.

Different stages and cases need different mechanical behaviour.

One thickness limits flexibility.

Final thought

If you want better clinical outcomes, stop treating aligner sheets thickness like a minor spec.

It’s not.

It’s a performance lever.

And once you start choosing thickness intentionally,

everything else works better.