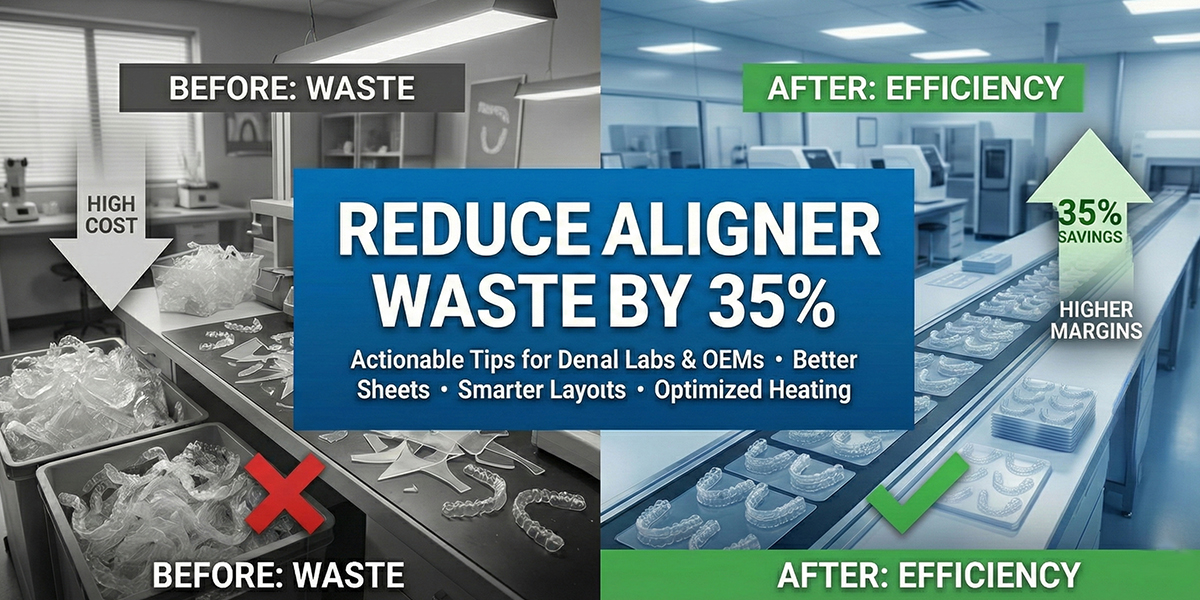

How to Reduce 35% Material Waste in Your Aligner Production — Tips for Labs & OEM Factories

Aligner material waste reduction.

Let’s talk about it.

Because if you’re running a dental lab or an OEM aligner factory…

You already know the truth:

Your biggest enemy isn’t the machine.

It’s the waste.

The silent thief eating your margins while no one notices.

And the worst part?

Most labs think waste is “normal”.

But once you see where it actually comes from…

You can literally cut 25–35% of your costs without changing your production volume.

I’ve seen it happen.

And today, I’m breaking down exactly how.

Why Waste Is Killing Your Costs

Simple truth:

The aligner business is low error tolerance.

One bad sheet.

One poor forming cycle.

One trimming mistake.

Boom — profit gone.

Here’s what people don’t talk about:

Waste doesn’t just come from “bad luck”.

It comes from predictable, repeatable production gaps.

Fix the gaps → you fix the waste.

Fix the waste → you fix your margins.

Let’s get into the real causes.

The 5 Hidden Waste Traps No One Talks About

1. Heating that’s either too hot or not hot enough

If the sheet overheats → bubbles, warping, dull finish.

If it underheats → it won’t pull deep, details are soft, forming is weak.

Both go straight to the bin.

2. Weak vacuum or pressure

If your pressure isn’t strong or stable, the sheet won’t wrap fully.

The aligner loses definition.

Even if it looks okay, the fit will fail.

Another sheet gone.

3. Low-quality aligner sheets

Inconsistent thickness.

Unstable heating window.

Materials that crack when trimming.

You’re not “saving money” by buying cheap.

You’re paying for waste.

If you want materials that actually form well, check these:

👉 High-performance PETG & TPU sheets

4. Bad model layout

Most labs don’t layout models efficiently.

They drop one arch in the centre

…leaving the edges wasted.

A small layout tweak alone can increase usable sheet area by 15–20%.

5. Trimming and finishing errors

The final 5% of the process causes 20% of the waste.

Over-cutting.

Uneven trimming.

Cracked edges on cheap PETG.

Fix the process → waste drops instantly.

Strategy #1: Use Sheets With a High Forming Success Rate

Here’s the deal.

Your material decides 70% of your waste rate.

Not the machine.

Not the operator.

The sheet.

A high-forming-ratio PETG sheet gives you:

More clarity

More consistent heating

Less cracking

Higher detail reproduction

More “first-try success” cases

If you want a starting point, here’s what I use and recommend:

👉 SmileFind® Aligner Sheets

These are stable.

Heat evenly.

Don’t bubble.

And most importantly:

They cut clean.

If your supplier can’t give you forming-rate test data, walk away.

Strategy #2: Optimise Your Heating Curve

Every sheet has a “sweet spot”.

Hit it → perfect forming.

Miss it → waste.

Quick rules that work across most PETG sheets:

Pre-heat to 170–200°C

Hold until the sheet reaches its sag point

Don’t rush the vacuum

Avoid hotspots (usually caused by uneven heating elements)

Small heating adjustments = big waste reduction.

Strategy #3: Fix Your Model Layout

This one is wildly underrated.

A tiny layout change can save thousands over a year.

Try this:

Angle the arch slightly

Push the model forward

Reduce unnecessary spacing

Use templates to standardise placement

This gets you more “usable area” without changing anything else.

Strategy #4: Standardise Your Cutting Workflow

Cutting errors are expensive.

Because you usually don’t spot the problem until late.

Here’s how to fix it:

Use consistent trimming guides

Keep blades sharp

Switch to PETG that doesn’t crack

Avoid “overheating” sheets before trimming

Train operators on cut depth

If your sheet cracks easily, it’s not your staff — it’s your material.

Mini Case Study — A Real Factory Dropped Waste by 38%

A mid-size OEM I worked with produced ~25,000 aligners per month.

Their biggest issue?

Inconsistent forming and brittle sheets.

What we changed:

Switched to higher forming-ratio PETG

Corrected heating curve

Standardised trimming

Improved model layout

Result:

Waste dropped by 38%

Throughput increased

Lead times improved

Same machines, same staff — just smarter workflow

That’s the power of removing waste.

How to Pick a Good Aligner Sheet Supplier

Here’s your checklist.

If your supplier fails any of these, move on:

Consistent thickness tolerance

Clear forming-ratio test data

Transparent material composition

Stable supply and MOQ flexibility

FDA/CE/ISO certificates

Sample testing available

If you want a supplier that ticks all the boxes:

👉 SmileFind® Aligner Sheets

FAQs

1. What’s a normal aligner waste rate?

10–15% is normal.

20–35% means you’re losing money.

2. Can material alone reduce waste?

Yes.

A better sheet can drop your failure rate immediately.

3. Is PETG better than TPU?

PETG = for aligners.

TPU = for retainers.

Different behaviours.

Different heating curves.

4. How fast can I see improvements?

Usually within 1–2 days after adjusting heating and switching material.

5. Do thicker sheets reduce waste?

Not always.

Quality > thickness.

Final Thoughts

Waste is a cost multiplier.

Cutting it down is the easiest way to increase profit in your aligner production.

Start with the material.

Fix the heating.

Fix the layout.

Fix the trimming.

If you want the simplest first step, test better sheets:

👉 SmileFind® dental teeth aligner sheets

Aligner material waste reduction is the fastest way to grow your business — and it starts with one smarter sheet.

Related Blog

Inquire Us Now

We will Get Back to You soon